![]()

If you're reading this article you're probably either a new truck camper owner or a person who is seriously thinking about buying one. Whatever your situation, it's a great move. The truck and truck camper combination is easy to drive, offers better fuel economy, is extremely versatile, and can be taken far off the beaten path. The truck camper is also easy to store and maintain, and in most states doesn't require annual

registration and title fees. But with no running gear, the truck camper is also the most unique RV in today's market. This means you'll need to buy the right pickup truck and buy the right truck camper equipment to safely haul it. This article addresses these and a host of other truck camper related topics to help make your transition to the truck camper world smoother and less difficult.

I. Choosing the Right TruckPayload, payload, payload! When it comes to hauling a truck camper, nothing is more important than this number. The payload of a truck is simply the amount of weight that the truck can carry and is a product of the truck's Gross Vehicle Weight Rating (GVWR). The payload, expressed in both pounds and kilograms, can either be found on a driver's side door pillar placard or in the glove box on a payload certification form. You can also determine the payload by subtracting the curb weight of your truck (you'll need to take it to the scales to get this figure) from the truck's GVWR. Basically, everything being carried in your truck, including all passengers, gear, and your "wet," fully loaded truck camper, should be below your truck's rated payload. Grossly exceeding the payload and GVWR is neither safe for your passengers nor for others who are sharing the road with you. And if you happen to get in an accident while overloaded, your insurance company can void out your coverage.

![]() |

| Choose wisely when buying your truck. Buy a one-ton. |

Another important rating when it comes to hauling a truck camper is the Gross Axle Weight Rating (GAWR). Each axle has an assigned GAWR, but the most important of the two is the rear since it will be bearing most of your cargo's weight. You can find these ratings by looking at the aforementioned axle and tire rating sticker or by looking at the truck's payload certification form. If you closely examine these ratings you should see an increase over the GVWR when totaling them. This increase can vary anywhere between from 100 to 1,000 lbs per axle. Exceeding the payload rating of a truck isn't advisable, but these ratings can be used to squeeze out extra pounds of cargo carrying capacity. One should never exceed the GAWR of your axles. The same applies to the weight ratings of your tires (more about that later).

Remember when the terms half-ton, three-quarter-ton, and a one-ton accurately represented the payload for each class of pickup truck? Well, those days are long gone with all three classes of truck capable of hauling much more weight. Today's three-quarter ton trucks have payloads between 2,300 and 3,800 lbs while one-tons can haul anywhere between 3,800 and 6,200 lbs. The large variances in each class are due to bed-size and options so they must be carefully chosen. For example, the 6.7L Ford Powerstroke diesel weighs 1,100 lbs wet compared to their 6.2L V8 gas engine which weighs in nearly half that at 600 lbs. And if you're considering a four-wheel drive transmission, that's another 400 lbs. The same applies to other nice-to-have options like steel wheels, a crew-cab, a super hitch and a winch; all of these add capability, but reduce payload. So choose your options wisely.

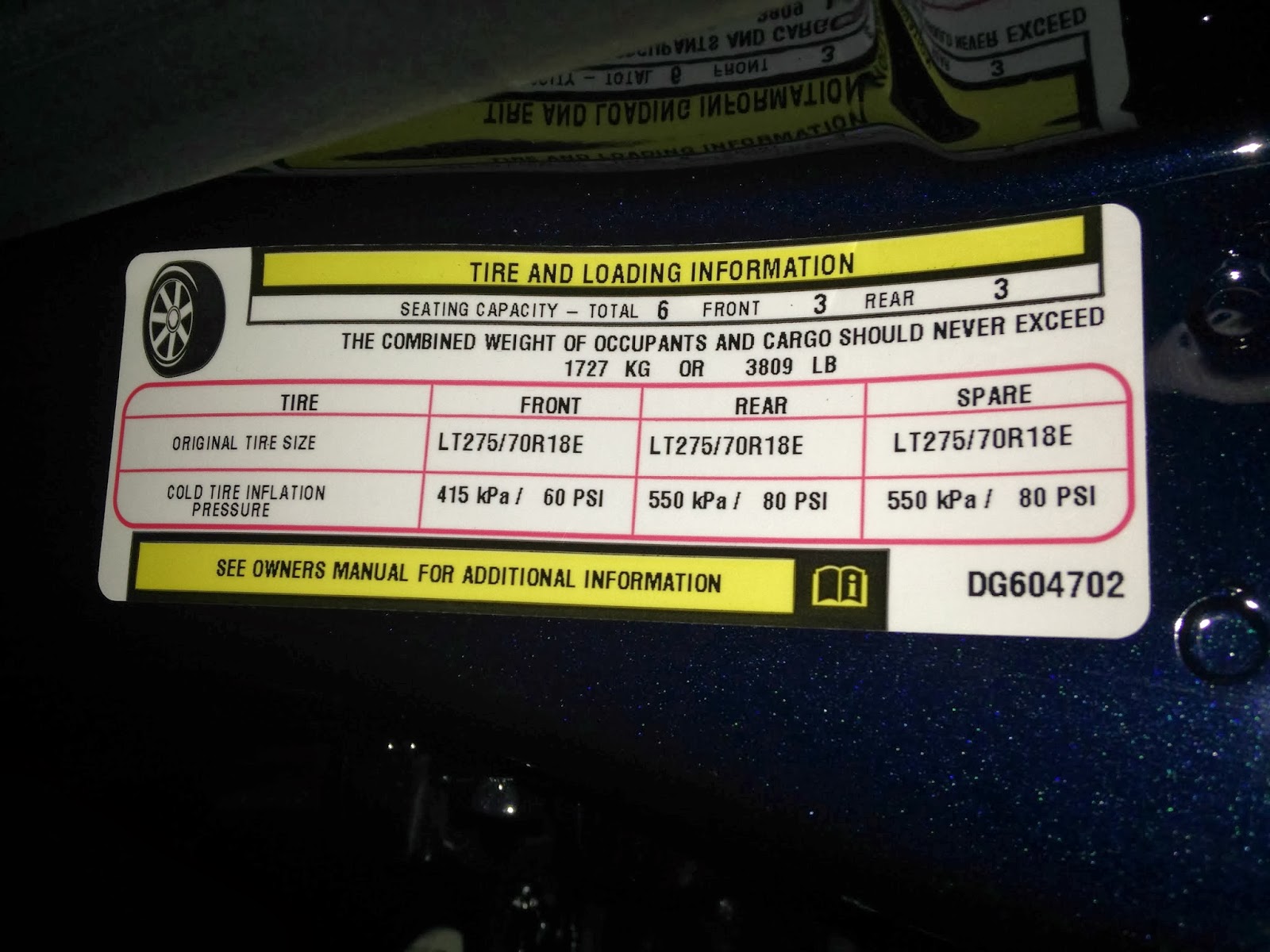

![]() |

| The official payload for this particular Ram 3500 is 3,809 lbs. |

When it comes to options perhaps the most often debated is whether to buy a truck with either Dual Rear Wheels (DRW) or Single Rear Wheels (SRW). Both certainly have their pros and cons. Dually's offer superior stability and handling on roads and usually offer much higher payloads, but they are also wider in the "hips" and less adept at off-roading. It's true that DRW's "float" better over certain surfaces like loose sand, but the big negative with them is that jagged rocks can get wedged in between the rear wheels causing flats and other damage. On the other hand, SRW trucks are narrower, lighter, more versatile, and provide superior traction and maneuverability on all types of road surfaces. Basically, where you intend on taking your truck camper plays a big role in what type of rear end to get. If you intend on staying on the asphalt with a heavy camper, then the DRW is the way to go. If you intend on doing a lot of off-roading with a light camper, then I'd go with the SRW.

The diesel engine is another hotly debated option. With the high cost of diesel at the pump and with today's strict EPA standards you'd think the diesel would be dead in today's auto and light truck market, yet it hasn't happened and probably never will. Diesels still provide superior torque, better fuel mileage, and last longer than the typical gas engine (600,000 miles is not uncommon). They also hold their value better and have a "coolness" factor associated with them that a gas engine can't touch. Yes, it's true that the new requirement for Diesel Exhaust Fluid (DEF) adds an additional burden for diesel ownership, but there's also no denying that today's diesel engine burns cleaner, is much quieter, and and doesn't have the smell associated with them that they had in the past. The big negative, of course, is the payload loss associated with the heavier engine (diesel engines typically weigh 600 lbs more than a gas engine), so this must be carefully weighed against the positives and your own specific needs. Because of this I wouldn't recommend a diesel for anything less than a one-ton truck.

So is the half-ton pickup truck suitable for hauling a truck camper? Yes, but with several caveats. It really depends on the truck's rated payload and the size and weight of the camper you have in mind. The 2012 Ford Heavy Duty F-150 long-bed (145 inch wheelbase), regular cab, 4x2 has a rated payload of 3,120 lbs. That's a pretty impressive amount of weight no matter how you slice it and dice it. Short-bed (6.5 ft) and mini short-bed (5.5 ft) models are much more limited than long-bed models due to their small payload (generally less than 1,900 lbs). This reduced payload basically limits you to pop-up truck campers and smaller hard-slide campers for short-bed trucks, and pop-up truck campers for the minis. With the exception of heavy duty models, short-bed half-tons will most likely require upgrades to the shocks, spring pack, and tires, the latter meaning an improvement to Load Range E tires.

II. Choosing the Right Truck Camper If you're starting from scratch and have neither a truck nor a camper, it's best to choose your camper first. This will save you angst and money in the long run. Today's consumer has much to choose from when it comes to buying a truck camper. Truck campers come in various sizes and styles including long bed and short bed, hard side and pop-up, and slide-out and non slide-out models. Like any RV, you'll want to buy the camper that meets your requirements as far as size and features are concerned. You'll also want to buy one that will allow you to go where you want. If you plan on doing a lot of

boondocking and off-roading then you should look hard at a pop-up truck camper. These are lighter, have a lower profile, and have a lower center of gravity for tackling the most challenging roads and terrain. If your travel plans are less ambitious, however, and you desire more security and a more capable four-season camper, then the hard-side truck camper will probably suit you better. That isn't to say, you can't do a lot of off-roading in a hard side truck camper. You can. But if you decide to go this route I recommend a non-basement model, with a low center of gravity, and a width of no more than 7.5 ft.

![]() |

| Today's truck camper consumer is blessed with many choices. |

When it comes to truck campers, weight is a very important consideration, if not the most important. Manufacturers list the unloaded "dry" and the fully loaded "wet" weights of their campers on their websites and brochures, but these figures can be deceiving. These numbers don't include installed options, like air conditioners, and never include things like food, clothing, cookware, utensils, and camping gear. Never buy a truck camper based upon the manufacturer weights alone. To give you a better idea of what the camper will actually weigh when you use it add 1,000 lbs to the camper's listed wet weight. This often-used rule of thumb works surprisingly well for truck camper owners and has proven to be pretty accurate when going to scales. Obviously, you'll want to ensure that the truck you choose has a payload rating higher than this more realistic camper weight figure.

An often overlooked factor when choosing a truck camper is how it's constructed. Aluminum framing is used by most truck camper manufacturers today, but there are several that still produce wood framed units. There are pros and cons to each. Aluminum is lighter, doesn't rot, and is mold and termite resistant, but it also more expensive, is subject to more thermal loss, and requires proper welds for the structure to hold up over time. On the other hand, wood is stronger, cheaper, easier to work with and repair, and insulates better, but is also heavier, can rot and mold over time if exposed to moisture. Wood also flexes better than aluminum. It's for this reason that some manufacturers that specialize in off-road campers--like Four-Wheel, Phoenix, and Northstar--use wood rather than aluminum for their frames.

Should you buy a truck camper with one or more

slide-outs? That's a personal choice. There are certainly some big positives with slide-outs, the most important being the extra space and roominess they create, but they're also heavy, tacking on an average of 400 lbs to the weight of the camper. Slide-outs can also leak, create drafts when extended (a major consideration for those who like to camp in the winter), and can breakdown. Like anything it really comes down to what's important to you. If you think you'll need the extra space that the slide-out provides and you think you'll camp mostly on well-maintained roads, then I would get one. But if you are planning on going off-road quite a bit and plan on doing a lot of exploring, then I would avoid them. The stresses they can create to the frame of the camper can eventually cause problems.

An important term you'll need to become familiar with when shopping for a truck camper is the truck camper's Center of Gravity (COG). Every camper has a COG which identifies where along the length of the camper the weight is centered. Basically, the camper's COG needs to be in

front of your truck's rear axle. Most campers have a sticker identifing where the COG is located to take some of the guess work out of it. You never want to have the COG

behind your rear axle because this will impair your truck's handling. Verifying that your COG is good is fairly easy and will require a couple trips to the scales with and without your camper. If your front axle weighs less with your truck camper on your truck then your COG is "off." You can usually correct this by reloading your camper, ensuring that most of the weight is in front of your rear axle.

III. Truck Camper EquipmentKeeping your camper anchored to your truck is obviously critical and is accomplished by using a combination of truck camper tie downs and turnbuckles. There are basically two tie down systems from which to choose: Torklift and Happijac. Both are fine systems with each offering several advantages and disadvantages. The big advantage of the Torklift system is that it bolts to the truck's frame underneath the truck bed and is a stronger more rugged design, while the Happijac system requires drilling into the truck's bed and rear bumper to install. The Happijac system does prevent side-to-side movement better and is probably better for off-road use, but the Happijac rear bumper tie down mounts have been known to fail under stress. All things considered, I prefer the Torklift system, but that's my personal preference. Check with your truck camper manufacturer to see which system they recommend. Warranties may be voided if you choose the wrong one. Four tie downs, two in the front of the camper and two in the rear, are needed to secure your truck camper to your truck.

![]() |

| Torklift Tie Downs and Fastguns. |

Turnbuckles are essential pieces of hardware in truck camper ownership. They act as the "middleman," securing the truck camper to the tie-down system of the truck. Strong winds, rough roads, and driving at highway speeds will test the ability of your tie downs and turnbuckles to control the forces or stresses working against your camper. Proper tension and installation of your turnbuckles is critically important. Make sure you read and understand the installation instructions for your turnbuckles to ensure they work optimally. For instance, too much tension can cause damage to your camper; too little tension can allow your camper to shift and slide while your drive. I use and highly recommend the Torklift FastGuns to secure my camper. For an in-depth review of the Torklift FastGun, check out my review

here.

The umbilical connection or "pigtail" provides your truck camper with the running, brake, and turn signal lights needed to be legal on the road. It also provides an important connection to your truck's alternator to charge your camper's battery while driving. The 6-pin receptacle for this connection is usually located on the driver's side front of the camper (though many pop-up truck camper manufacturers place the 6-pin receptacle in the back). Due to this placement, truck camper owners will often install a standard 7-pin electrical RV receptacle on the driver's side, front of the truck bed. But another perfectly acceptable option is to simply run an extra-long umbilical from the front of the camper to the 7-pin receptacle at the rear of the truck. Remember, only six wires are needed for a truck camper since the truck camper doesn't have its own brakes (the brakes run on the blue wire). For a more detailed look at the pigtail wiring for truck campers, please click

here.

The ability to tow is one of the great things about owning a truck camper. An important thing to keep in mind when towing, however, is that the tongue weight of the trailer must be factored in against the truck's rated payload. A boat, horse, or utility trailer will typically have a tongue weight anywhere between 200 and 500 lbs, depending on the size of the load (tongue weight, of course, will not be a factor when towing a vehicle "four-down"). Moreover, if you want to tow, you'll probably need a hitch box extension since many truck campers extend anywhere from 18 to 24 inches from the rear of the truck. Available in different lengths, a hitch box extension is simply a metal tube that fits into a standard hitch receiver.

IV. Truck Suspension and TiresNothing is more important to the handling and safety of your truck than your tires. Together, they bear the entire weight of your truck and truck camper combo. If you plan on hauling a truck camper, you'll generally want Light Truck (LT) tires with at least a Load Range rating of E. However, not all Load Range E tires are created equal. Sizes and weight ratings differ, so you'll want to ensure that the tires you're looking at can handle not only the weight of your truck, but also the weight of your truck camper. And if you're upgrading your tires, you should also seek additional load capacity over the OEM ratings. Keep in mind that the weight on the rear axle is evenly divided by each tire, so an axle with a GVWR of 6,200 lbs will come with tires rated for 3,100 lbs. The maximum inflation value for Load Range E tires is 80 psi.

Proper inflation of your tires is vital--check them regularly. Refer to your truck's documentation and the door jamb sticker to determine the correct inflation rating for your tires. For example, the door jamb sticker for a 2013 Ram 3500 truck with LT275/70R18E tires calls for 60 psi for the front tires and 80 psi for the rear. These values are for hauling the maximum payload of the truck, so the tire pressure in the rear can be lowered if you're hauling less that the maximum payload or nothing at all. Make sure you check your tires regularly for abnormal wear and proper inflation, especially before leaving on each trip. As for the size of the tires, that's a personal choice. Those who haul around long-bed truck campers, the heaviest campers on the market, swear by 19.5 inch tires (Load Range H) because of the stiffer sidewalls and how well they handle with the extra weight.

As for the type of tires to put on your pickup truck, it depends on where you live, the kind of roads on which you travel, and where you like to camp. If you live in an area where winter ice and snow are the norm and you like to winter camp, you'll want to have a good set of stud-less snow tires to provide the traction you'll need. For those who plan on doing primarily highway driving and who live in a temperate climate, then a good set of all-season highway tires will be more than sufficient. Another great option is a quality set of all-terrain (A/T) tires. These work well for both highway driving in all conditions as well as off-road travel and are an excellent alternative for those who don't want to bother with a specialized tire. As for my favorite brands, I really don't have one. Over the years I have purchased all-terrain tires from several manufacturers, including BF Goodrich, Firestone, Toyo, and Michelin, and have liked them all and got excellent service out of each.

![]() |

| Typical spring pack for an unloaded one-ton truck. |

Most people know how critical wheels and tires are to truck handling and safety, but the truck's suspension system is important, too. The suspension system consists of coil springs and leaf springs as well as shock absorbers and linkages that connects the chassis to the axles and wheels. All combined these components directly contribute to a truck's handling and braking and play a major role in driving pleasure and comfort.

My philosophy on suspension upgrades is simple. It's best to drive your truck with your camper mounted first to see how it handles before spending any money on upgrades. Otherwise, you may waste a lot of money on hardware you really don't need. I see this happen all the time. Based upon the opinion of friends and what they've read on Internet forums, new truck owners will immediately shell out big bucks on new shocks, air bags, and Stableloads before even buying or taking a test drive with their truck camper. This is backwards. It's best to first see how your truck handles under load and treat each symptom that you encounter with the correct suspension modification. Moreover, only one modification should be made at a time to determine its true effectiveness.

If you find that your truck sags too much in the rear with your camper mounted you'll need to make some changes. The most common remedies for rear sag include leaf springs, Torklift Stableloads, and air bags. Of these, adding another leaf spring is probably your best bet as they provide a much better ride and much improved spring travel compared to a truck with Stableloads or a large overload spring. Stableloads, however, are an effective modification, too. By engaging the overload spring sooner, they not only prevent sag, but they can also prevent sway and improve control. If you do decide on Stableloads, I recommend the quick disconnect version as they can be engaged or disengaged in a matter of seconds. The last viable option to correct rear sag are air bags. They're easy to use, adjustable, and are great for side-to-side loading when one side is lower than the other, but they can also can create too much roll when they are overfilled and aren't particularly suitable for off-road use.

![]() |

| A Firestone Ride Rite Air Bag. |

The shocks that came with your truck may or may not be up to the task of carrying the extra weight of a truck camper. The dampening effect of your shocks is important in how well your truck and camper rides when going over rough and uneven roads and terrain. Shock absorbers comes in two basic forms: self-adjusting or manual. Self-adjusting shocks, like the Bilsteins or KYBs, do exactly that, they adjust based upon the force asserted each time they're depressed. Manually adjusted shocks, such as the Rancho 9000, allow you to change how much dampening is applied based upon the weight you are carrying. The adjustment can be made either on the shocks themselves, the cheaper option, or within the cab with a spendy remote unit. The pros and cons of each are pretty obvious, it comes down to personal preference and cost.

For those who are experiencing excessive sway or roll on sharp turns you can try the aforementioned Torklift Stableloads or a sway bar like the Hellwig Big Wig. Both are excellent products, but work differently. Stableloads work with the leaf springs to engage the overload springs sooner while the sway bar works with the axle and frame of the truck to keep the truck level. Most of the three-quarter and one-ton trucks coming off of today's assembly lines come with a front sway bar only, but many find that a rear sway bar is also needed for added stability and handling when hauling a truck camper. Some truck owners have even replaced the front OEM sway bar with a beefier aftermarket sway bar and saw a noticeable improvement in handling. For an in-depth review of the Hellwig Big Wig, click

here.

V. Truck Camper Loading and StorageLike hitching a trailer, perfectly backing your truck underneath your camper takes a little practice. When backing in it's best to align the camper with some reference point in the truck bed. I like to use painter tape placed in the center of the camper and in the center of the truck bed as reference points. It doesn't matter what you use as long as it works for you. For the whole process it's best to have another person spot for you as you back in your truck. This way you can ensure that the yaw of your camper is straight and is perfectly aligned in the middle of your truck bed. Electric jacks make all the difference in the world when raising and lowering your truck camper and makes the whole process of loading and unloading your camper much easier and quicker. If you don't have them, I strongly recommend that you get them. You won't regret it.

![]() |

| The Dee Zee heavyweight bed mat. |

Another consideration in truck camper loading is whether or not to use a thin, heavyweight bed mat. Personally, I think they're a must. The mat not only protects your bed or spray-on bed liner from being scratched, but also prevents your truck camper from sliding around while driving your truck. You can buy specially made mats for the specific make and model of your truck or you can go cheap and buy generic anti-fatigue floor mats like those sold at the big box stores. Having tried both, I prefer the former. These fit better and prevent your camper from sliding around better than generic mats. I now use a Dee Zee heavyweight truck bed mat in my Ram 3500.

Should the tailgate be left on or removed from your truck? It depends on the length and model of the truck camper, but in most cases, the camper won't load properly with the tailgate on, so it needs to be removed. Even if your camper does load with the tailgate down, you should still remove it. When it comes to truck campers every pound matters, especially when that weight is behind the rear axle. Why haul a 60 to 80 lb tailgate when you don't need to? It only takes a few minutes to remove and with it off you don't have to worry about the paint getting damaged by stones being kicked up from underneath.

When it comes to supporting your truck camper off the truck, some manufacturers recommend that you do, and some don't. Newer campers with aluminum frames appear to be engineered better to handle the stress where the jacks are attached to the camper's frame, while older one's aren't. So if you have an older wood frame model from, say, the 1990s, you may want to provide additional support for your camper. It's best to refer to your owner's manual to see what is recommended by the manufacturer. As for what to use to support your camper, there are many different ways to do it. Perhaps the simplest and most effective way is to glue and screw several 1x6's together and stack them is such a way to provide sufficient support.

.jpg)